Evaluating or analysing risk in the workplace can become tricky to navigate, with so many factors to take into consideration.

In this guide, we explain how you can evaluate and control risk in the workplace confidently, for the benefit of your employees and business.

Key Points:

- Risk assessment is the determination of whether the level of risk is acceptable or needs to be reduced

- As well as keeping your employees health a priority, risk assessments also show external parties you’re doing everything possible to comply with health and safety laws

- There a five steps developed by the Health and Safety Executive (HSE) that give a clear outline when it comes to risk assessment; Identify any hazard, Assess the risks, Control the hazards, Record what you find, Review your processes

What is Risk Assessment?

Risk assessment is the determination of whether the level of risk is acceptable or needs to be reduced.

Even with the best will in the world, you are only going to be able to assess the risks that are reasonably foreseeable, or in legal terms, “reasonable to attribute to a person”. The law covers this in management regulations, and in health and safety courses, where we use knowledge tests to assist with the determining of these terms:

- Common – which any reasonable person could identify

- Industry – well known in the industry you’re in

- Expert – which is knowledge outside of most competencies and is very specific

In basic terms, we are being held to account for our decisions. These terms are used to determine if the risk identified could have been seen by anyone, known in the industry or could only be dealt with by an expert. Only then are we benchmarked accordingly.

Example. When I was working in the steel industry, I was looking at the paints that we used to spray our steel-work. As I was evaluating the risk and what was reasonably foreseeable, I didn’t think that my common knowledge would provide me with a balanced view on how to control and work with the paint.

So, I went to the manufacturers (the industry) and asked for their safety data sheets. Assessing those, I still didn’t feel that I could undertake a suitable and sufficient risk assessment, so I called an expert in the field who provided me with her knowledge and as a result, we produced a suitable risk assessment.

Why Do Risk Assessments?

Risk assessments show that you’re putting your team’s wellbeing at the heart of everything you do by minimising the risk to them.

As well as keeping your employees health a priority, risk assessments also show external parties you’re doing everything possible to comply with health and safety laws.

They also help you to spot any potential problems before those issues become bigger than you can handle.

How Often Should You Do Risk Assessments?

Carrying out a risk assessment once a year is a good idea, but you should also be carrying out risk assessments when:

- There are complaints within the company of unsafe practices or continuous illness among staff

- There are any changes to the level of risk to your team

- There are any new jobs introduced that pose a level of risk

- Any of your employees become pregnant and are in a environment where there are risks to the health of the team member and their unborn child

Who Is Responsible For Managing Risk?

Only qualified and experienced people should attempt to carry out risk assessments.

You may appoint someone internally, or hire an external candidate to carry out the assessment.

Whoever is responsible for managing risk should be fully trained and able to make an accurate judgment call to protect your team and your business.

What Are The Five Steps Of Risk Assessment?

The five steps were developed by the Health and Safety Executive (HSE) to give a clear outline when it comes to risk assessment. They are:

- Identify any hazards – this could be anything that poses a hazard to health, including handling substances

- Assess the risks – who could be harmed by the hazards you’ve discovered, and how?

- Control the hazards – can you eliminate it altogether or take steps to contain it?

- Record what you find – write down your findings so you can look back and reflect

- Review your processes – you’ll need to assess whether the controls you’ve put in place are working or not, and adjust them accordingly

*A good place to start is with the 5×5 matrix.

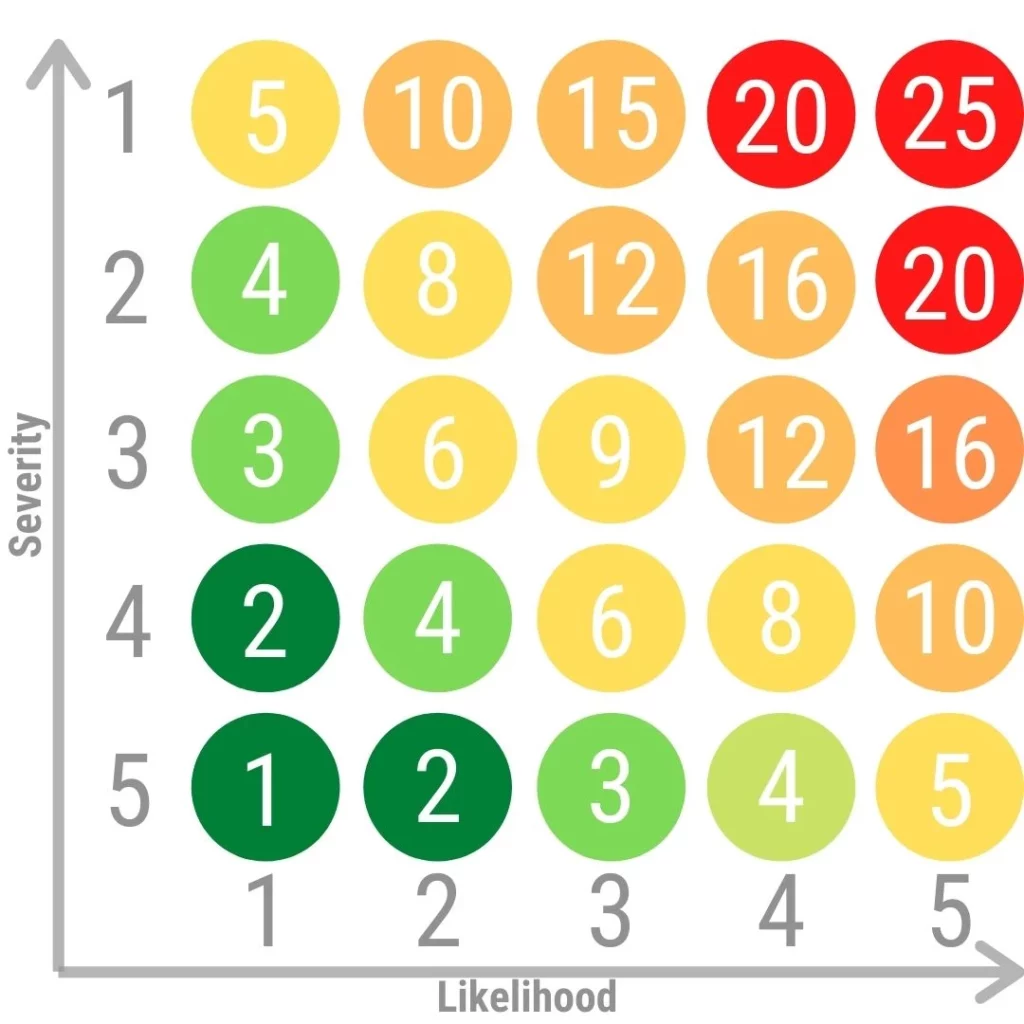

How to Evaluate & Assess Risk: The 5×5 matrix

Most companies might start evaluating whether the hazard needs further control by using a 5×5 matrix, that looks something like this:

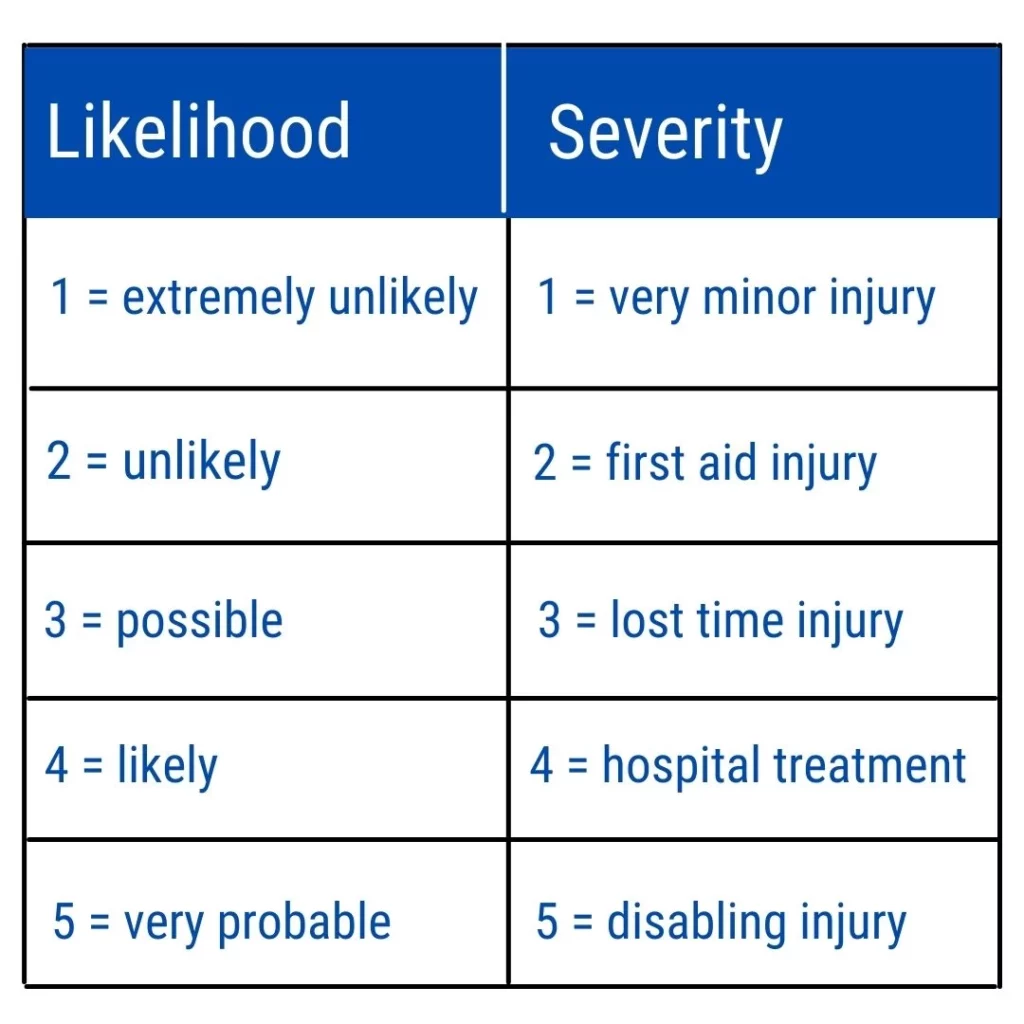

*Note above that every number on the side and the bottom has a meaning.

If we take it back to the paint risk assessment, for example; the likelihood of inhaling the paint when spraying is likely (4) and the severity of harm could over time be a disabling injury like kidney damage (5), and as we don’t currently have Respiratory Protective Equipment (RPE), then the result is Red and Unacceptable.

The sum looks like this:

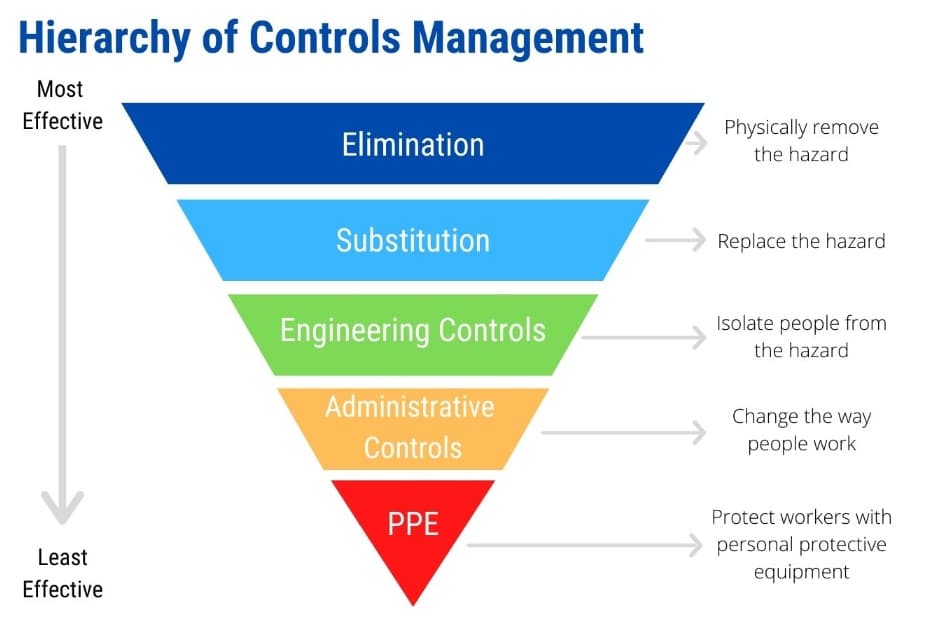

Controlling & Justifying Risk: Hierarchy of Controls Risk Management

Now we have evaluated the risk with what’s currently in place, and found it to be red (unacceptable), we can put controls in place to attempt to bring the value down.

We can use the Hierarchy of Control to help us prioritise what controls we should consider and in what order:

Whatever control we decide to use, we need to be able to justify our choice. For example, if we decide on PPE (or RPE) in this case, which is the least effective, we have to be able to justify why we were unable to eliminate the substance altogether, or use substitutions instead.

Once we have put the additional controls in place, we are then able to re-rate the risk and we should find that the rating decreases, like this:

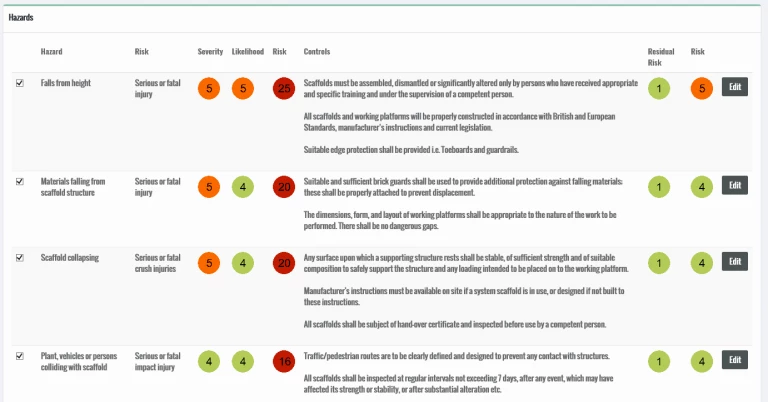

You can see a worked example here of how this translates on to the risk assessment.

Image source: bsgltd.co.uk

Over to you

These are only a few examples to show how it could look, but it’s now over to you. If you need any help or support in evaluating and controlling risk in your workplace, get in touch with us.