Kaizen is a Japanese term that means “change for the better” or “continuous improvement”. It’s been adapted by organisations as a business strategy to help make small changes over time.

Large-scale changes within the workplace can make employees feel unsure, worried and even disinterested in a job they may previously have loved.

Kaizen philosophy isn’t about fixing a particular problem nor does it have a specific goal. The only aim is to make the organisation, its products and people better. It’s all about making a safe place where leaders and their teams feel confident enough to admit their mistakes and learn from them.

⏰Key Points:

- Kaizen became popular in 1986 due to Masaaki Imai’s book “Kaizen: The Key to Japan’s Competitive Success”, and it has been used by companies including Toyota, Pixar and Nestle.

- The purpose of Kaizen is to take small steps to implement change and make continuous improvements.

- This works out better for your teams, because they have time to adapt and contribute to these changes, and it doesn’t all happen at once.

What are the five principles of Kaizen?

Kaizen has five principles to help you discover opportunities for improvement and learning:

- Know your customer: Work out what customers want and value so you can improve their experience

- Let it flow: Make zero-waste a company-wide goal and encourage your employees to reduce their waste

- Get to gemba: “Gemba” means “the actual place” in Japanese, meaning you should go to where value can be created and take action

- Empower people: Make sure your teams have the clarity, knowledge, equipment and systems they need to succeed

- Be transparent: Make improvements tangible by using data, so your teams can see the impact they’re having

What is the importance of Kaizen? Why do businesses use it?

Kaizen is an important philosophy for businesses because it maximises quality and productivity while limiting waste.

It’s one of the 12 pillars of the Toyota Production System. It was incorporated when Masaaki Imai started working with them after his experiences observing American business practices.

💡A working example of Kaizen – Toyota💡

Toyota uses Kaizen to empower their employees to figure out where improvements are needed and make suggestions on how to implement them, no matter their role. This allows their employees to take accountability, use their initiative and be flexible in their approach to work.

Once Kaizen was more widely understood after the mid 1980’s, more businesses started adopting it. Ed Catmull, Pixar’s co-founder, has discussed how Pixar was inspired by the openness and creativity that Kaizen brought to Japanese companies that use it.

💡A working example of Kaizen – Pixar💡

Pixar encourages all of its employees to share their honest opinions to find problems within the creative process of making films. If you’re looking for more detailed information about how Pixar encourages creativity, trust and hard work, take a look at Bill Capodagli and Lynn Jackson’s book “Innovate the Pixar Way”.

💡A working example of Kaizen – Nestle💡

Another company that uses Kaizen is Nestle. In this case, it was implemented to help reduce factory waste – by using value stream mapping (VSM), which we’ll look at later – and to change the company culture by asking employees what they valued and making improvement a responsibility for all.

Advantages and disadvantages of using Kaizen

Advantages of Kaizen include:

- An easier change: small, gradual changes require less effort and are usually met with less resistance

- Focus on quality: taking more care with processes means minimal waste and errors

- Improved morale: your employees are empowered and feel more valued

- Better relationships: everyone has an equal voice and is encouraged to participate

- Customer focus: employees will better understand the needs of your customers

- More reliable systems: with more robust practices, your teams will have what they need to succeed

There can also be a few difficulties with Kaizen, such as:

- Unenthusiastic uptake: organisations with exclusive and negative cultures will need to improve this first to encourage employees to be open to the Kaizen method

- Short term benefits: if you don’t implement Kaizen into your company’s everyday culture, it can be hard to sustain your employee’s interest in it

How can business leaders use Kaizen to create positive change?

There are various tools you can use to help incorporate Kaizen and make positive changes.

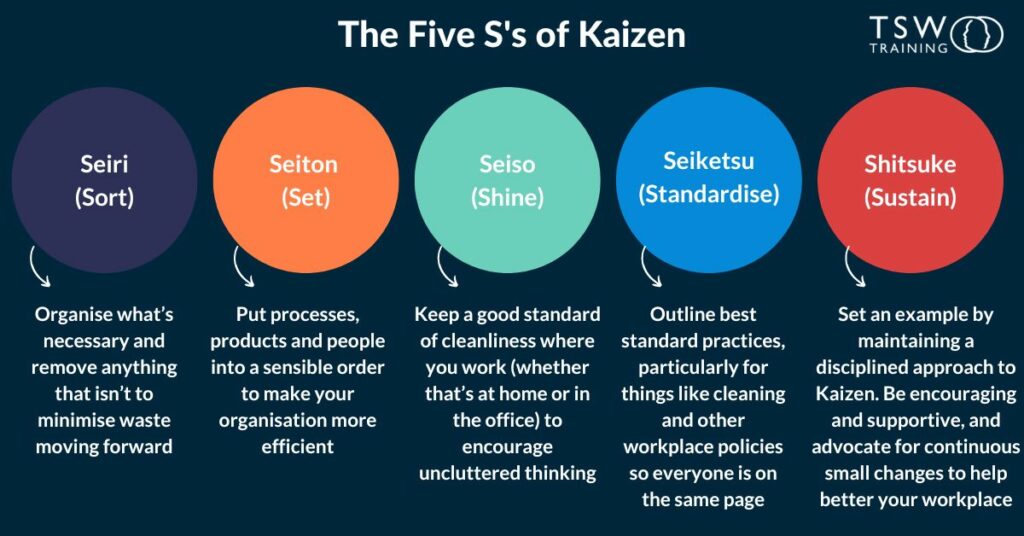

The five S’s are a key part of the Kaizen philosophy to better your organization’s profits, efficiency, service and safety.

Here are the five S’s in Japanese and their English counterparts:

- Seiri (Sort): Organise what’s necessary and remove anything that isn’t to minimise waste moving forward

- Seiton (Set): Put processes, products and people into a sensible order to make your organisation more efficient

- Seiso (Shine): Keep a good standard of cleanliness where you work (whether that’s at home or in the office) to encourage uncluttered thinking

- Seiketsu (Standardise): Outline best standard practices, particularly for things like cleaning and other workplace policies so everyone is on the same page

- Shitsuke (Sustain): Set an example by maintaining a disciplined approach to Kaizen. Be encouraging and supportive, and advocate for continuous small changes to help better your workplace

Another way to use Kaizen to make positive changes is the plan, do, check, act (PDCA) method – also known as the Shewhart cycle or Deming cycle.

It’s a repetitive model that involves:

#1. Plan

Work out the problem and find the cause.

💡Example – there’s lack of product knowledge within a new team you’re leading

#2. Do

Create a solution, implement it and decide how you’ll measure it.

💡Example – you implement a product induction training for these new team members and progress is marked with a test and discussion at the end of the course.

#3. Check

Make sure it’s working as expected.

💡Example – check their training progress and test results and speak to the team to see if they now feel more confident with the product

#4. Act

Make a note of the results.

💡Example – the test results and talks with your team show the training was a success so you raise it with senior stakeholders so it can be rolled out across the company for all new starters

And then get ready to start the PDCA cycle all over again, either for problems that have been raised by this solution or on a completely different topic.

Value stream mapping (VSM) is a technique that Pixar used to improve their bottling factory’s efficiency. It involves visualising – like with a diagram or sketch – the key steps of the product or service journey from start to finish and using this to identify areas which can be streamlined by reducing waste, saving time or any other sort of improvements that would make the process and/or end product better.

As well as the ones above, there are many more methods you can use to implement Kaizen in your organisation, including the five W’s (what, when, where, why, and who) to problem solve, just in time (JIT) inventory management and Kanban open communication techniques.

How can Kaizen be used to build a positive culture at work?

Business leaders can use Kaizen to improve customer and staff satisfaction. If you listen to the needs of both the people who work for you and those who buy your products then you’ll have happier staff and customers. This can also lower some business costs as you won’t waste time on things that aren’t important – and time is money!

This satisfaction can lead to increased productivity – your employees will feel more motivated to work for an organisation that cares about its impact on its staff, customers and the planet.

Using Kaizen to find value and make gradual improvements can also help lower staff turnover rates and achieve a boost in loyalty to the organisation. This is because staff won’t feel disrupted by large changes and will feel confident and safe in the knowledge that they’re allowed to fail and learn from their mistakes. Giving your employees an equal voice will empower them and lessen the divide caused by organisational hierarchy.

Being open about your employee’s contributions and letting them see the improvements through tangible data can increase confidence and motivation. Kaizen can also enhance your team’s problem solving skills and develop stronger relationships as they’ll need to consider things like how to reduce waste and various other ways to make improvements.