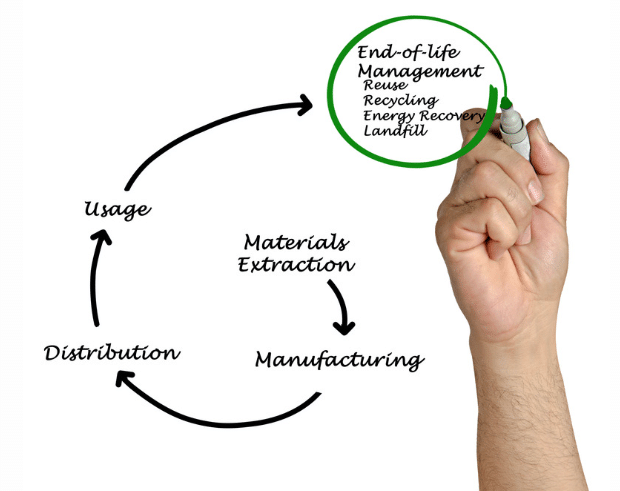

Every product has a beginning and an end – a ‘life’. This life begins when the product is made, ending when it is no longer of use.

♻️Key Points:

- These days, our global economy is moving increasingly towards its goal of becoming a circular economy. This is where waste is recycled into the manufacture of another product or service.

- The ultimate aim is to increase the life cycle of each product to such an extent that it never becomes waste.

- This has brought the life cycle of the items we produce and consume under intense scrutiny from an environmental perspective.

What is life cycle analysis?

In simple terms, life cycle analysis (LCA) is the measurement of a product’s impact on the environment throughout its ‘life’, from the time it is made until it is discarded.

But it doesn’t just stop at products – materials, processes and services can also be measured and evaluated by LCA.

There are different types of LCA, depending on what is being measured and the timeframe needed to generate results.

- Cradle-to-gate analysis only assesses a product until it leaves the factory gates. It means a simpler LCA can be performed to provide quicker insights.

- Cradle-to-cradle analysis substitutes the waste stage of a product’s life cycle with the recycling stage. This is relevant to the circular economy, changing the cradle-to-grave life cycle by ‘closing the loop’.

- Cradle-to-grave analysis covers the entire lifespan of a product that results in waste and is not recycled.

The four stages of LCA

An LCA follows the pattern of a science experiment, where one begins with a hypothesis or belief and follows a methodology to obtain results and then a conclusion.

There are four main stages of an LCA:

#1. Goal and scope

This sets out what we want to measure – for example, a product or service. It also looks at which specific parts of the life cycle will be analysed and the impact category (such as CO2 emissions), as well as what to exclude from the analysis.

#2. Inventory analysis

Here is where data is collected – all relevant inputs and processes identified in stage 1. For example, this could include details of raw materials and energy use, as well as any useful data available from the supply chain.

#3. Impact assessment

This stage involves translating the data to show impacts. These are categorised as outlined in stage 1, such as CO2 emissions or potential for global warming.

#4. Interpretation

Here is where the real in-depth analysis takes place. How high are emissions? How do different products compare? Can processes be improved? What are the biggest challenges?

Why do we need an LCA?

Businesses are under pressure to drastically reduce their environmental impact.

From consumer demand to pressure groups to government legislation to reach net zero targets by 2050, there is no more space for greenwashing.

Every company needs a sustainability strategy, ideally with science-based targets to show real value in activities to achieve efficient use of resources and reduce waste.

When an LCA is performed accurately, within strict parameters, it can provide a wealth of valuable data that can support science-based sustainability initiatives and inform decision-makers.

♻️Explore our range of IEMA courses to give your businesses the expertise to reduce its carbon emissions and work towards net-zero & green transition.♻️

What are the benefits of using LCA for a business?

#1. Achieves stakeholder buy-in

An LCA can be a huge help to a business’ sustainability manager. Not only does an LCA find and measure specific issues regarding environmental impact, thus informing decision-making, it can also be used to inform decisions and build stakeholder buy-in.

An LCA ideally leads a sustainability manager to set science-based targets for the company to achieve. Decisions should be made regarding processes that you have measured.

#2. Gets everyone on board

If each team or department is given specific goals to help the environment based on LCA findings, this can galvanise employee support as they will want to work together to achieve something good for the planet, as well as for the business.

#3. A thriving future

Sustainability is good for business. It is those businesses that take their responsibilities seriously and use science, innovation and technology to make positive change that will thrive and prove their resilience and adaptability.

Climate change is here to stay and businesses not only need to deal with today’s issues, but plan for future challenges.

#4. Helps businesses comply with regulations

When claiming its sustainability credentials relating to a product or service – whether it be on packaging or in reports to stakeholders – a company must now prove compliance with laws and regulations.

Note. This is often also be relevant to the tendering process, where a company must prove its environmental credentials in order to beat competitors and win contracts. Conducting an LCA should now be an essential part of such a process, proving the environmental footprint of a product or process.

#5. Clears the path to achieving sustainability

An LCA helps companies prove they have reduced environmental impact or enhanced the life cycle of a product. It will help management make sustainable decisions, guide sustainable product development, prove claims of sustainability and help find better, more sustainable suppliers.

New products need to have low environmental footprints, creating as low emissions as possible and minimum waste.

#6. Builds a better future for the planet

An LCA can inform the creation of new products by helping research and development teams to compare materials and processes and examine how they influence the environmental impact of the end product.

An LCA can also help evaluate the supply chain. Perhaps your product or service has a negative environmental impact because of one of your suppliers involved somewhere along the life cycle.

Choosing the right suppliers is not only related to cost and an LCA can help influence these decisions by highlighting potential issues in the chain.

Examples of successful LCAs

@oceanbottle, https://www.instagram.com/oceanbottle/

Ocean Bottle

This company aims to reduce the amount of plastic in the ocean, forming partnerships to encourage the collection of plastic waste as well as its reuse. Its goal is to prevent seven billion plastic bottles from entering the ocean by 2025.

With their reputation intrinsically linked to their sustainability credentials, the team at Ocean Bottle conducted a Life Cycle Analysis (LCA) of their core products, including calculating the Greenhouse Gas (GHG) emissions emitted by the 500ml Ocean Bottle over its lifespan.

The data collected mapped GHG emissions at each stage of the life cycle, with a detailed analysis. Different scenarios were presented for transportation, recycled material content and manufacturing energy sources.

This gave Ocean Bottle the crucial facts needed for the decision-making process in building a robust and ambitious emissions reduction strategy.

The organisation also used the findings to push others in the industry to do the same, with the shared goal of reaching net zero.

@Sole Fly, https://www.instagram.com/solefly/

Nike

The global sportwear giant was looking to move towards using innovative, environmentally friendly material for its products.

But with such a huge following as a major influencer, any claims regarding sustainability were inevitably going to be under great scrutiny.

The company performed an LCA to compare traditional leather and new material Flyleather, manufactured from leather scraps.

Nike intended to use environmental claims for their marketing activities, so the new material needed to be tested and compared with the existing leather used in the manufacture of their shoes.

Once it was proven that Flyleather had a lower environmental footprint than leather, Nike had the LCA refined to look into its supply chain in more detail – such as farm, slaughterhouse and tannery.

The difference between materials was found to be significant for the majority of analysed categories, meaning Nike could boast about its new material’s environmental benefits in their marketing.