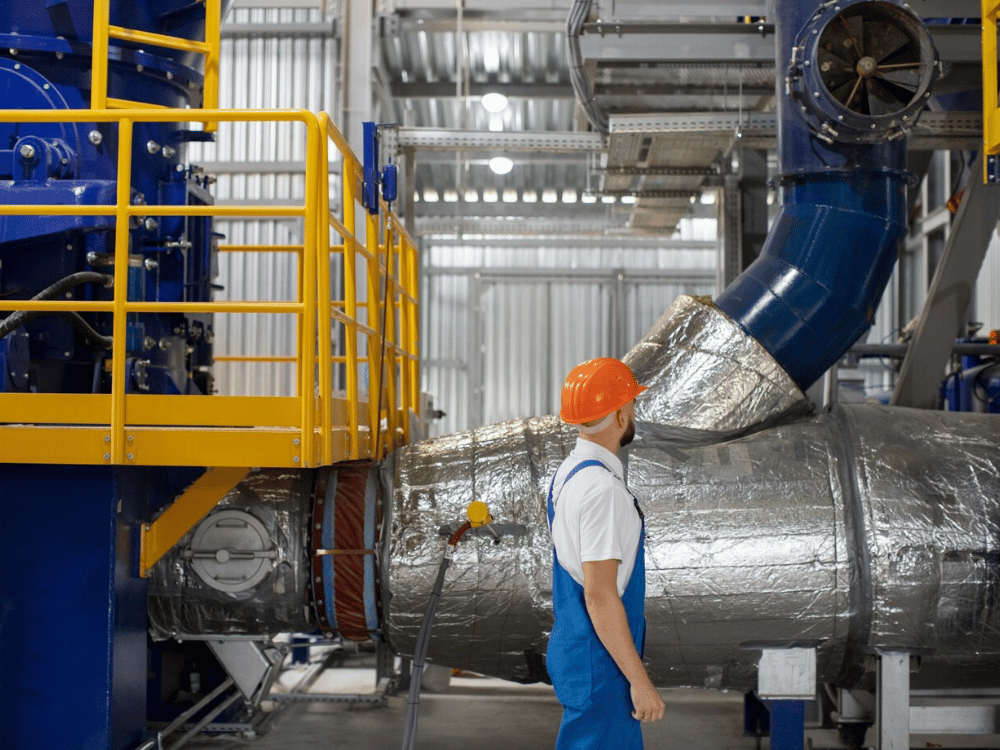

A manufacturing company in West Yorkshire was fined £200,000 by the Health & Safety Executive (HSE) 2023. The fine resulted from three workers being injured in an explosion while operating a furnace at their Todmorden site.

The Dangerous Substances and Explosive Atmospheres Regulations 2002, or DSEAR Regulations, are in place to help protect workers against exactly these situations.

One key element to safeguarding worker safety is a thorough DSEAR risk assessment.

In this blog, we’ll tell you everything you need to know about these crucial checks, including what they cover and who can carry them out.

TL;DR – How to Carry Out DSEAR Risk Assessment

We will cover the main components of DSEAR risk assessments shortly.

But for a brief overview, robust checks should include these elements:

- Identify dangerous substances

- Determine substance uses

- Assess associated risks and who could be harmed

- Control or prevention measures

- Risk mitigation

- Reporting of findings

- Schedule regular follow-ups

Discover how market-leading health and safety courses from TSW Training can bring your team up to speed with the DSEAR risk assessment regulations now.

What is a DSEAR Risk Assessment?

Unlike a standard occupational safety and health (OSH) risk assessment, DSEAR risk assessment providers focus on risks that could lead to fires, explosions, or the release of dangerous substances.

Those checks also hone in on the risks attached to metal corrosion as a result of dangerous substances around your workplace.

Having said all this, where DSEAR assessments are similar to standard OSH checks is in the fact that you still need a specialist party or competent person to carry them out.

As a side note, although the legislation does cover elements of hazardous substance control, it is a separate set of laws from those outlined in the COSHH regulations.

What are ATEX and DSEAR?

While navigating the DSEAR Regulations, you will undoubtedly come across the term ATEX.

ATEX, a shortened term for “Atmospheres Explosibles,” is the name given to two EU Directives that seek to control explosive atmospheres and ensure the safety of products being used in those environments. The two core Directives in question are ATEX 137 and 114.

ATEX 137, also known as “Workplace Directive” or Directive 99/92/EC, covers minimum requirements for employers around providing suitable health and safety protections for workers at risk of explosive atmospheres.

Meanwhile, ATEX 114 (also known as Directive 2014/34/EU) places requirements on equipment manufacturers and suppliers. The laws dictate that all equipment intended for use in explosive atmospheres, whether electrical or mechanical, must meet specific health and safety requirements.

However, in the UK, directives covered under ATEX are also effected under Regulation 7 and Regulation 11 of the DSEAR legislation.

ATEX 114 rules are covered through Regulation 5 of the BIS Equipment and Protective Systems Intended for Use in Potentially Explosive Atmospheres Regulations 1996.

What are DSEAR Zones and HAC?

We should first talk about HAC to cover ‘zones’ and their DSEAR risk assessment meaning.

HAC or Hazard Area Classification defines an area of your premises depending on the likelihood of a gas or flammable vapour existing in the atmosphere.

Once the size of the flammable atmosphere has been calculated, any equipment being used in that location must pass the requirements laid out in Regulation 5 of the BIS Equipment Regulations highlighted above.

Moving on to DSEAR zones then, the regulations define zones as:

“Any place in which an explosive atmosphere may occur in quantities such as to require special precautions to protect the safety of workers”

HAC leverages zones to determine the frequency and duration of explosive atmospheres occurring in the workplace:

- Zone 0: Explosive gas atmosphere is present continuously or for long periods.

- Zone 1: Explosive atmosphere will likely occur as part of standard operation.

- Zone 2: Explosive atmosphere is unlikely in normal operation and, if it occurs, will only exist for a short time.

Based on these zones and assessments, DSEAR and the HSE set out equipment selection guidance. These controls highlight the equipment that may be safely used in such areas.

Benefits of a DSEAR Assessment

When it comes to reviewing the benefits of conducting robust DSEAR risk assessments, there can be no greater prompt than preventing a risk to life.

As we mentioned in the introduction, explosive atmospheres in the workplace can have lethal circumstances. The incident we mentioned earlier is not an isolated case either.

For example, a 46-year-old man passed away at a recycling centre in Perth in March 2023. Plus, an explosion at a military pyrotechnics factory took the life of a 19-year-old man in January 2023.

Regular DSEAR assessments can help minimise the hazards and risks your employees face.

In addition, compliance with DSEAR assessment regulations can also highlight due diligence in the event of an incident on your premises.

But what components should a comprehensive check include?

How to Carry Out DSEAR Risk Assessment

The HSE highlights that robust DSEAR risk assessments should cover three core areas:

- Detection of dangerous substances in the workplace

- Work activities and equipment used around those substances

- Do the substances and works place employees and other premises occupants at risk?

However, as with any other safety checks – such as fire risk assessments – it pays to have more stages in place with your DSEAR reviews.

We’d also suggest including these vital elements in your assessment:

- Implement steps to remove or reduce risks

- Record all findings of the assessment

- Define emergency preparedness processes

- Schedule another review in 12 months

Who Can Carry Out a DSEAR Risk Assessment?

To maintain compliance with DSEAR regulations, you should ensure that a competent professional carries out risk assessments.

You can budget for external specialists to come into your space and conduct these checks annually. Alternatively, you could choose to develop your team’s skills by creating your own competent person via our health and safety training.

Once passed, qualified personnel can complete regular checks on behalf of the responsible person. Taking this avenue could have several benefits for your business, including:

- Cutting down on annual spend

- Developing talent from within your company

- Checks are completed by someone familiar with your premises

- Professional development opportunities promote a positive workplace safety culture.

What Does DSEAR Require Duty Holders To Do?

DSEAR places a responsibility on duty holders to assess and remove or mitigate risks within their premises.

However, there are more steps to understand in this risk mitigation process. So, let’s define those more clearly now.

Assess Risks

Completing robust risk analysis on DSEAR areas means evaluating several points.

- Risk analysis: A detailed risk analysis is the perfect place for duty holders to start when it comes to completing DSEAR risk assessments. This includes identifying and listing dangerous or explosive substances.

- Substance Information: Duty holders should define the name of the substance identified. Additionally, details about the substance’s category, flash point, and ignition temperature should be recorded.

- Substance Usage: Evaluate what the substance is used for in the workplace. Are there any less hazardous alternatives on the market?

- Risk Assessment (with Rating): Duty holders are required to schedule regular DSEAR risk assessments. These checks should evaluate elements like:

- Hazard identification

- Evaluation of existing controls

- Considerations around who could be harmed

In addition to those checks, appropriate recordings and plans for regular reviews should be kept on file.

- Documentation and Other Actions: Regulation 5 of DSEAR dictates that employers with five or more employees should record the assessment findings.

- Recommendations and Completion: Employers should outline DSEAR ACOPs (Approved Codes of Practice) for safe working processes moving forward.

Prevent or Control Risks

Regulation 6 of DSEAR outlines that employers have a duty to ensure that the risks from dangerous substances are eliminated – as far as is reasonably practicable.

Implement Control Measures

Employers can analyse the risks associated with dangerous substances and prevent those wherever possible.

However, where ordinary work necessitates being around these substances, the regulations mandate the following control measures be implemented:

- Reduce the quantity of dangerous substances

- Minimise instances of release

- Control releases at the source

- Prevent the formation of an explosive atmosphere

- Collect, contain and remove releases to a safe place

- Avoid sources of ignition

- Avoid adverse environments (eg temperature or control parameters)

- Segregate incompatible substances.

Mitigate Risks

In addition to those control measures, Regulation 6 also requires duty holders to outline safe working practices for the areas or substances highlighted in the risk assessment.

There are several ways employers can fulfil this requirement, including:

- Training: Place workers in health and safety training courses to enhance awareness of DSEAR-compliant working practices.

- Personal Protective Equipment (PPE): Provide workers in DSEAR zones with suitable PPE.

- Appropriate equipment: Ensuring that plant equipment and tooling comply with Regulation 7.

- Waste disposal: Regulation 5 of DSEAR also mandates that employers should include procedures for appropriately disposing hazardous, explosive or dangerous substances. Licensed waste contractors should dispose of items like paints, solvents, inks, and other chemicals.

Prepare Emergency Plans and Procedures

Of course, accidents can still happen even with all these measures and processes in place. So, employers need to have clear and concise emergency preparedness plans in place.

In fact, DSEAR Regulation 8 highlights that employers must ensure that:

“Procedures, including the provision of appropriate first-aid facilities and relevant safety drills (which shall be tested at regular intervals), have been prepared which can be put into effect when such an event occurs.”

Similar to your fire strategy plan, businesses should have enough trained fire wardens in place to facilitate the execution of emergency plans.

What is Covered in DSEAR Risk Assessment Training?

Comprehensive DSEAR risk assessment training should include modules surrounding:

- Duties of employers under DSEAR and Fire Safety Order 2005

- Definitions of dangerous substances and explosive atmospheres

- A list of substances and activities covered under DSEAR

- Understanding of how explosions and fires occur in the workplace

- Deep coverage of the regulations to clarify the DSEAR risk assessment meaning

- Accepted processes for the safe handling, storage and transport of dangerous substances

As you can see from this brief overview, getting your team qualified for DSEAR compliance through health and safety courses is incredibly important.

Frequently Asked Questions (FAQs)

Here are some frequently asked questions regarding DSEAR risk assessments:

What is a DSEAR Risk Assessment Example?

An example of a DSEAR risk assessment would include identifying dangerous substances or explosive atmospheres. The next step is reviewing the works surrounding those elements and who could be harmed before developing ways to reduce risks and reporting the review findings.

What is the Required DSEAR Assessment Frequency?

DSEAR risk assessments should be completed regularly. However, the regularity of checks may be dictated by the environment. Standard offices could complete checks every five years. On the other hand, higher-risk environments like quarries or power stations should aim to complete annual assessments.

When is a Separate DSEAR Risk Assessment Needed?

DSEAR risk assessments are required whenever work being carried out by an employer or self-employed person involves or could involve dangerous substances. Or when potentially explosive atmospheres are detected.

Conclusion

Those workplace explosion fatality statistics should be enough to encourage employers to remain DSEAR compliant.

Completing regular DSEAR risk assessments is a great way to ensure your standards don’t slip.

Utilise our range of health and safety training courses to allow DSEAR legislative knowledge to permeate your team and ensure compliance.